At BP Solutions Group, we've seen a significant shift in how brands approach label production over the past decade. Digital label printing has revolutionized the industry, offering new possibilities that weren't available with traditional label printing methods alone. This comprehensive guide will help you understand why digital label printing might be the perfect solution for your brand's needs.

Understanding Label Printing Methods: Traditional vs. Digital

Before diving into the benefits of digital label printing, it's important to understand how it differs from traditional methods.

Traditional Label Printing Methods

Traditional label printing has been the industry standard for decades, with flexographic printing being the most common technique:

Flexographic Printing:

- Uses rubber or photopolymer plates to transfer ink to the label material

- Requires separate plates for each color

- Excels at large print volumes (10,000+ labels)

- Known for consistent color reproduction across large runs

- Higher setup costs but lower per-unit costs at scale

Digital Label Printing Explained

Digital label printing operates more like the printer in your office—but with industrial-grade precision and quality:

How It Works:

- Uses digital files sent directly to the printer

- No plates or mechanical setup required

- Prints all colors simultaneously using CMYK process (plus white and specialty colors)

- Variable data capability allows easy customization between labels

- Immediate setup with minimal waste

Key Digital Technologies:

- Inkjet: Sprays microscopic droplets of ink onto the label material

- Laser/Toner: Uses electrostatically charged particles for precise color application

- Hybrid Systems: Combines digital printing with conventional flexo printing

7 Compelling Reasons to Choose Digital Label Printing

1. Cost-Effective Short Runs

One of the most significant advantages of digital label printing is its cost-effectiveness for short to medium production runs.

Why This Matters:

- No plate costs or setup fees means lower initial investment

- Economical for runs between 50-100,000 labels

- Allows startups and small businesses to access professional label quality

- Pay only for what you need without minimum order requirements

- Perfect for limited edition products, seasonal variations, or test marketing

2. Rapid Turnaround Times

In today's fast-paced market, speed is often crucial for brand success.

Digital Advantage:

- No plate making

- From approved artwork to finished labels in days, not weeks

- Rush orders can often be accommodated

- Faster market entry for new products

- Quick response to market trends or regulatory changes

3. Superior Print Quality

Modern digital label presses produce exceptional quality that meets or exceeds traditional methods.

Quality Features:

- High-resolution printing (up to 1200 dpi)

- Smooth gradients and photographic reproduction

- Fine text clarity even on small labels

- Consistent color throughout the run

- Sharp, clear barcodes and QR codes

- Ability to reproduce complex designs with precision

4. Unlimited Customization

Perhaps the most exciting aspect of digital label printing is the ability to customize each label.

Customization Options:

- Variable data printing for sequential numbering or codes

- Personalized labels with different names or messages

- Region-specific information on the same print run

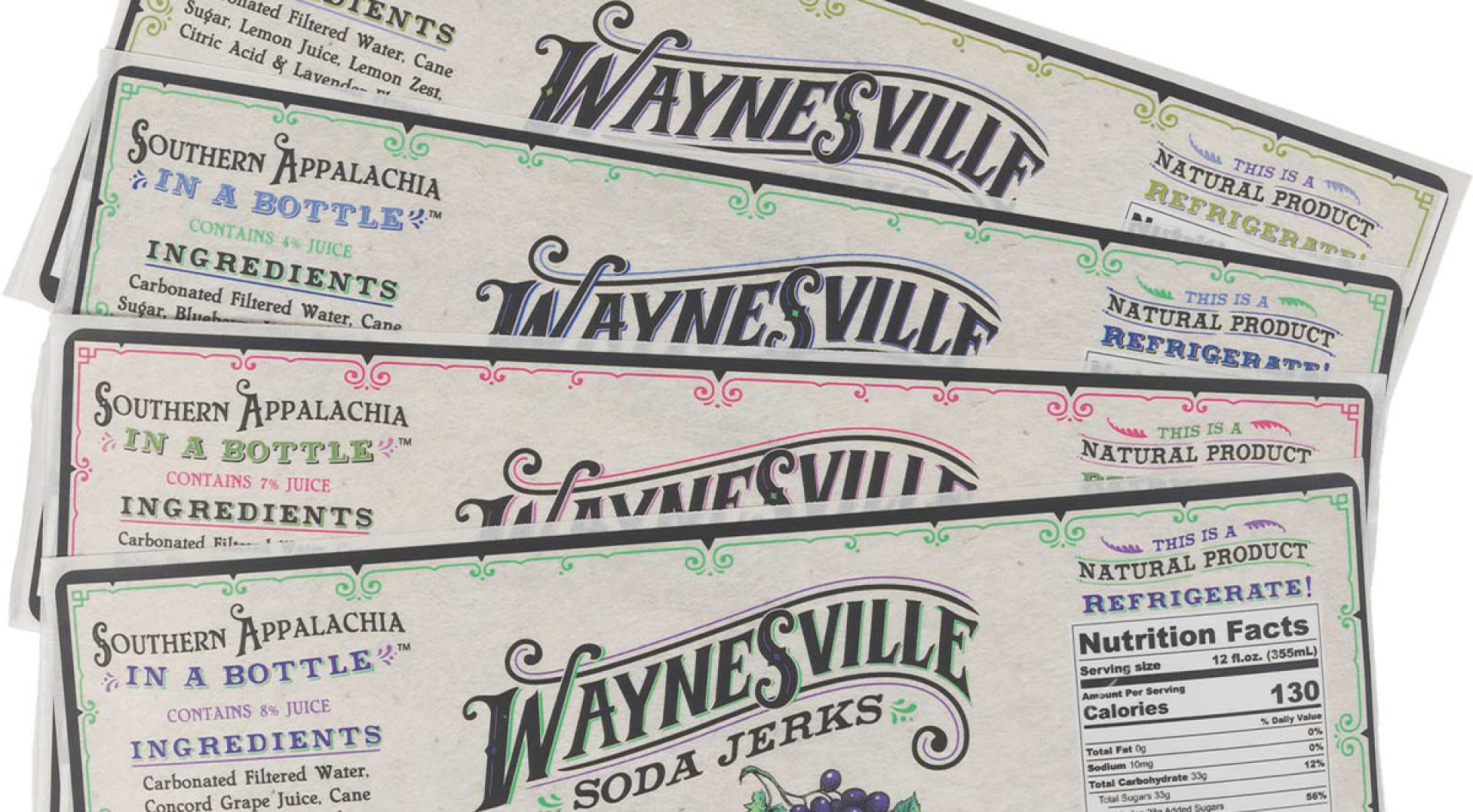

- Multiple SKUs or flavors in a single run with shared design elements

- A/B testing different label designs with minimal additional cost

For craft beverage producers, this means printing multiple beer varieties with the same label template but different flavor information or alcohol content. For cosmetics companies, it enables personalized customer names on special edition products.

5. Color Accuracy and Consistency

Digital printing offers remarkable color consistency that's difficult to achieve with traditional methods.

Color Benefits:

- Consistent color from first label to last

- No variation between print runs when using the same material

- Special color matching capabilities

- Ability to print brand colors with precision

- Option to include white ink for clear or metallic substrates

6. Sustainable Advantages

As brands increasingly focus on sustainability, digital label printing offers several environmental benefits.

Eco-Friendly Features:

- Significantly reduced waste during setup

- Less energy consumption than traditional presses

- No plate-cleaning chemicals

- On-demand printing reduces inventory waste

- Reduced carbon footprint from shorter production cycles

7. Material Versatility

Digital label printing works on a wide range of materials, giving brands flexibility in their packaging decisions.

Compatible Materials:

- Paper stocks (uncoated, semi-gloss, high-gloss)

- Films (clear, white, metallic)

- Sustainable options (recycled content, compostable films)

- Specialty substrates (textured papers, estate papers)

When Digital Label Printing Makes the Most Sense for Your Brand

While digital printing offers numerous advantages, it's important to determine if it's the right choice for your specific needs. Here's a practical guide to help you decide:

1. Perfect For Small Businesses and Startups

If you're just launching your product or running a small business, digital label printing aligns perfectly with your needs:

- Budget-Friendly Entry: No expensive plate costs or minimum orders

- Professional Appearance: High-quality labels that compete with larger brands

- Flexibility: Easy updates as your brand evolves

- Scalability: Start small and increase quantities as you grow

2. Ideal for Product Testing and Market Validation

Before committing to large label orders, digital printing allows you to test concepts:

- Multiple Designs: Print several versions to gauge market response

- Small Quantities: Produce just enough for market testing

- Quick Iterations: Easily refine designs based on feedback

- Reduced Risk: Minimal investment before full market launch

3. Smart for Complex Product Lines

Brands with numerous SKUs or variations benefit significantly from digital printing:

- Efficient Multiple SKU Production: Print different flavors, scents, or varieties in a single run

- Color Variations: Maintain design consistency while changing color schemes

- Language Variations: Create multilingual versions without additional setup

- Seasonal Products: Easily produce limited-time offerings

4. Essential for Limited Edition or Seasonal Products

Products with a finite sales window find digital printing particularly advantageous:

- Just-in-Time Production: Print only what you need for the season

- Quick Turnaround: Get limited editions to market faster

- Design Updates: Easily refresh designs for next season

- No Obsolete Inventory: Avoid wasting labels when the promotion ends

Cost Comparison: Traditional vs. Digital Label Printing

Understanding the financial implications of your printing choice helps make informed decisions:

1. Setup Costs

Traditional Flexographic:

- Requires investment in printing plates for each color in your design

- Die cutting tools needed for custom shapes

- Significant press setup time required before printing begins

- Proof costs for ensuring design and color accuracy

Digital:

- No plate costs—files go directly from design to press

- Still requires die cutting tools for custom shapes

- Minimal press setup time compared to traditional methods

- Digital proofs are typically more affordable and faster to produce

2. Volume Economics

Traditional Flexographic:

- Higher initial investment due to setup costs and plate creation

- Lower cost per label as quantity increases

- Most cost-effective for large print runs

- Reprints require minimal additional setup if no changes are made

Digital:

- Little to no setup costs make small runs economical

- Consistent cost per label regardless of design complexity

- Less economical at very high volumes

- Reprints and design changes don't incur additional setup costs

3. The Crossover Point

The "crossover point" is where traditional printing becomes more cost-effective than digital. While this varies by project, consider these factors:

- Design Complexity: Digital costs remain stable regardless of color count, while traditional methods cost more for each additional color

- Run Frequency: Multiple small runs favor digital, while single large runs may favor traditional

- Design Changes: Products requiring frequent updates benefit from digital's flexibility

- Total Quantities: Higher volumes generally favor traditional methods

- Label Size: Larger labels consume more digital ink, potentially shifting economics

4. Beyond Direct Costs

When evaluating total cost of ownership, consider these additional factors:

- Inventory Management: Digital's print-on-demand capability reduces warehousing costs

- Obsolescence Risk: Smaller digital runs minimize the risk of wasted labels due to product changes

- Cash Flow: Digital allows for just-in-time production, spreading costs over time rather than requiring large upfront investments

- Market Agility: Digital's quick turnaround enables faster response to market opportunities

- Customization Value: The ability to personalize or regionalize labels may provide marketing advantages that offset any premium in direct costs

Quality Comparison: Traditional vs. Digital Labels

Label quality impacts how consumers perceive your product. Here's how the two methods compare:

1. Image Quality

Traditional Flexographic:

- Excellent solid color reproduction

- Potential for slight registration issues on fine details

- Limited capability for gradients and subtle shading

- Consistent reproduction of spot colors

- May have minor variations throughout long runs

Digital:

- Superior reproduction of photographs and complex images

- Perfect registration of multiple colors

- Excellent gradient reproduction and fine details

- Consistent color throughout the entire run

2. Durability

Traditional Flexographic:

- Excellent lightfastness with proper inks

- Superior abrasion resistance

- Good chemical resistance

- Proven long-term performance

Digital:

- Improving lightfastness with new ink formulations

- Good abrasion resistance with proper coatings

- Good chemical resistance

- Continuous improvements in durability

3. Special Effects

Traditional Flexographic:

- Superior metallic and specialty ink application

- Better application of heavy solids and opaque whites

- Excellent results with specialty varnishes

- More options for textured finishes

Digital:

- Good capabilities for specialty effects

- Digital foil and embellishment options

- Options for textured finishes

- Hybrid solutions combining digital printing with floxographic printing

Making the Transition: From Traditional to Digital Label Printing

If you're currently using traditional label printing methods, transitioning to digital doesn't have to be an all-or-nothing approach:

1. Hybrid Approaches

Many brands find success with a hybrid strategy:

- Use digital for product launches, limited editions, and small-volume SKUs

- Maintain flexographic printing for high-volume, established products

- Gradually transition more products to digital as the technology evolves

- Use digital for prototyping before large flexographic runs

2. Overcoming Transition Challenges

When switching to digital, be aware of these potential challenges:

- Color Matching: Establish color standards that work across both platforms

- Material Consistency: Ensure consistent materials for a uniform brand appearance

- Design Optimization: Adjust designs to leverage digital strengths

- Inventory Management: Develop systems for tracking smaller, more frequent orders

Working with BP Solutions Group for Your Digital Label Needs

At BP Solutions Group, we specialize in helping brands maximize the benefits of digital label printing:

Our Digital Label Printing Capabilities

- High-resolution digital label presses

- White ink capability for clear and metallic materials

- Variable data printing for customization

- No plate charges or setup fees

- Rapid turnaround times

- Comprehensive color management system

- Wide range of material options

- Expert guidance on design optimization for digital

- Competitive pricing for short to medium runs

The BP Solutions Group Advantage

Our approach to digital label printing is focused on your brand's success:

- Consultation to determine the best printing method for your specific needs

- Design support to maximize the impact of your labels

- Material recommendations based on product requirements

- Quality control throughout the production process

- Flexible quantities to match your exact needs

- Consistent results from run to run

- Expert technical support from our experienced team

Conclusion: Is Digital Label Printing Right for Your Brand?

Digital label printing offers compelling advantages for many brands, particularly those with diverse product lines, frequent design changes, or smaller production volumes. The technology continues to advance, making digital an increasingly attractive option even for applications traditionally dominated by conventional printing methods.

For startups, small businesses, craft producers, and brands looking for flexibility and customization, digital label printing provides an ideal balance of quality, cost, and capabilities. Even larger brands are finding value in digital for certain aspects of their product lines, particularly limited editions, regional variations, and product testing.

At BP Solutions Group, we're committed to helping you navigate the complexities of label printing decisions. Whether you're launching a new product, refreshing your current labels, or looking to optimize your packaging costs, we have the solutions to help your brand shine.

Ready to Explore Digital Label Printing for Your Brand?

Contact BP Solutions Group today at 828-252-4476 or visit our website to discuss your label printing needs. Our label specialists can provide samples, quotes, and expert guidance to help you determine if digital label printing is the right choice for your brand.